Technical approach

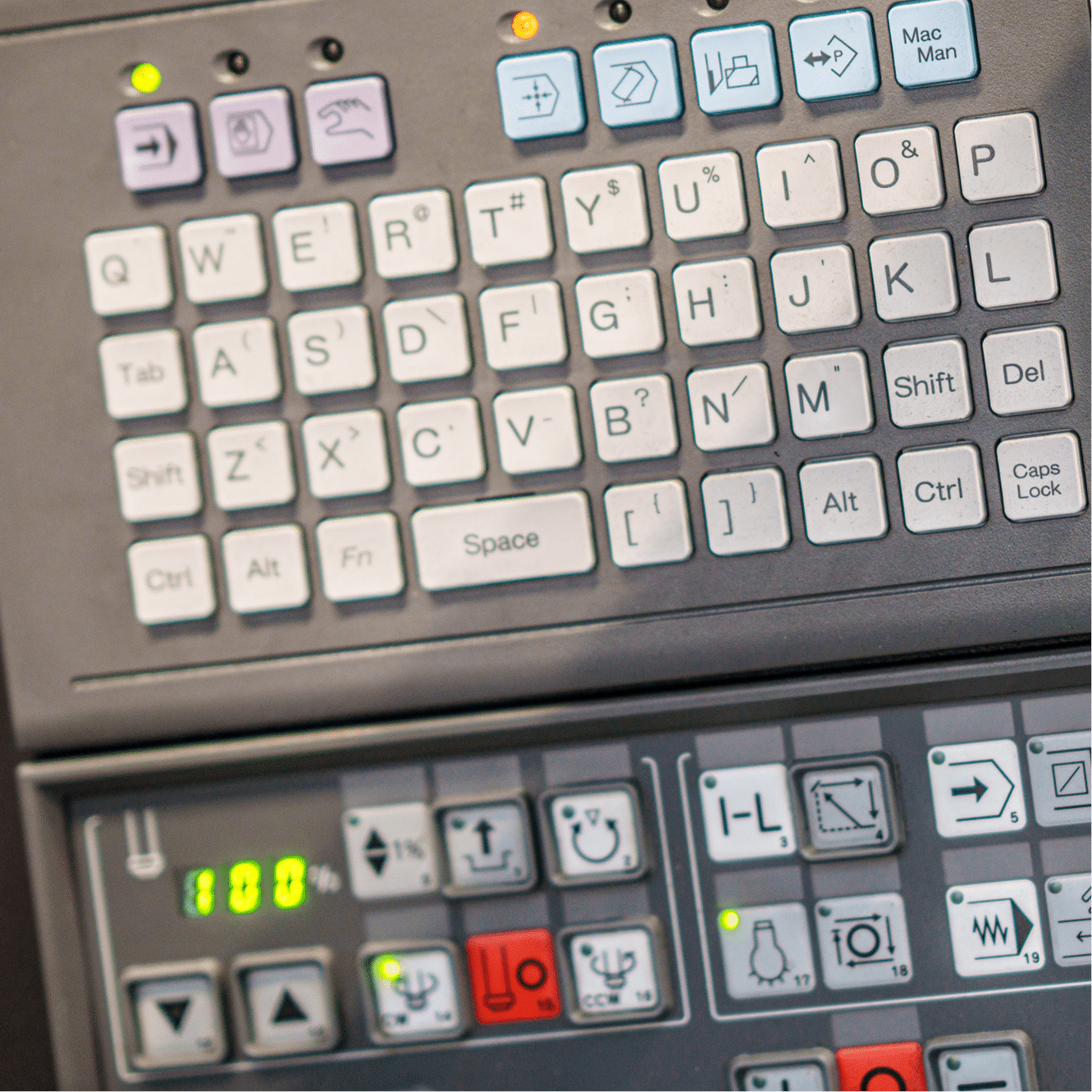

Production took place entirely in-house. Thanks to our turning and milling department and permanent partners for post-processing, all steps could run in parallel. Using Hypermill and Hyperturn, we programmed the parts and produced them on automated CNC machines with continuous size control. Through smart planning, all parts, including post-treatment, were ready within four weeks.

Results and added value

Within four weeks, TMI Group delivered complete, post-treated parts that allowed the customer to restart their assembly line. This kept the delivery of machines to their customers on schedule. This case underlines what sets TMI apart: flexibility, technical knowledge and a strong internal organization. When it comes down to it, we switch quickly, without compromising on quality or precision. As a result, our customers know they can count on us, just when it really counts.