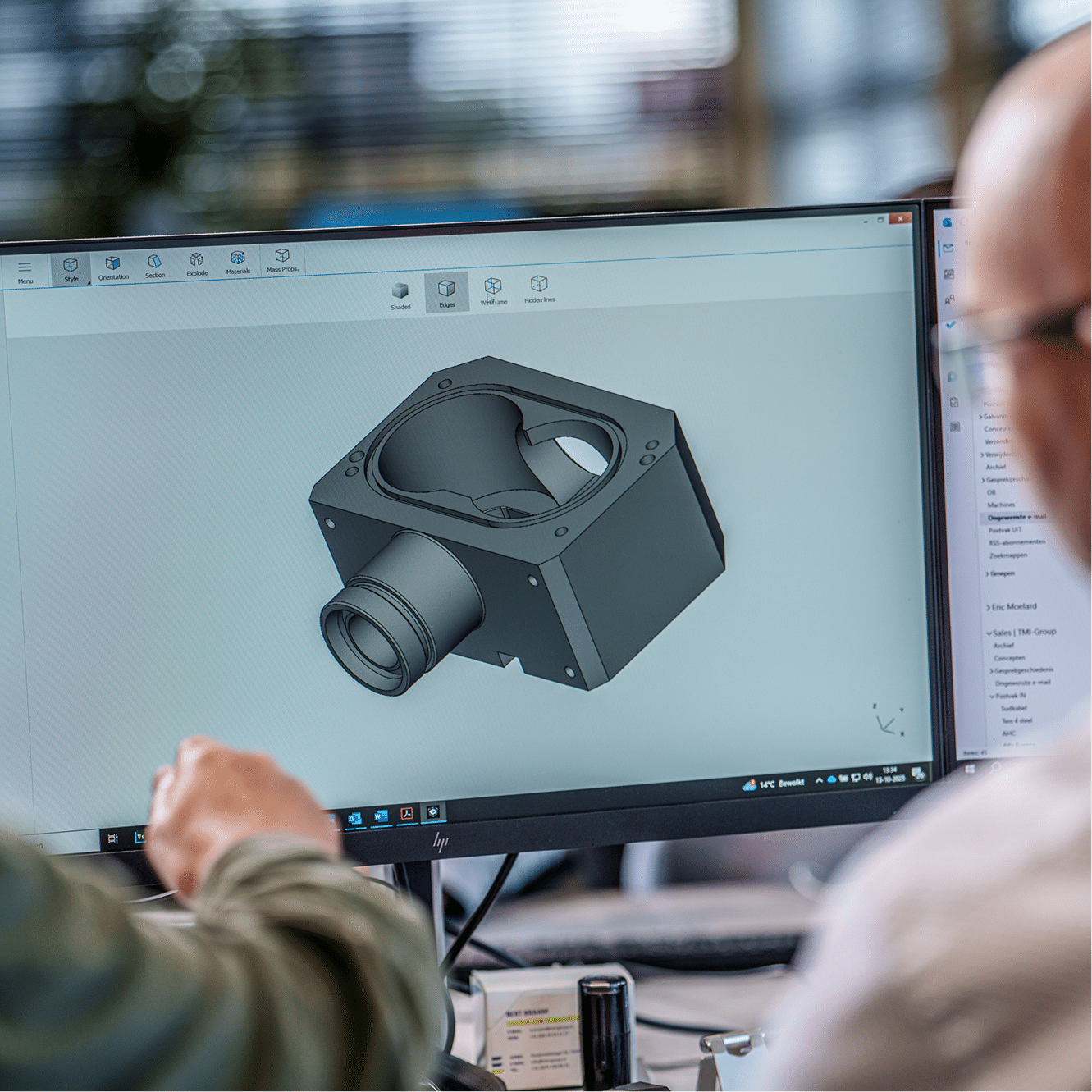

Precision stainless steel work for the food industry (TMI-Machining)

For a client in the food industry, TMI Group produced a complex component: a pump housing made of 316 stainless steel. Due to the combination of turning and milling operations, tight tolerances and hygienic requirements, this product required extreme precision. In close cooperation between our programmers and the customer, a feasible design emerged that fully met the technical specifications.