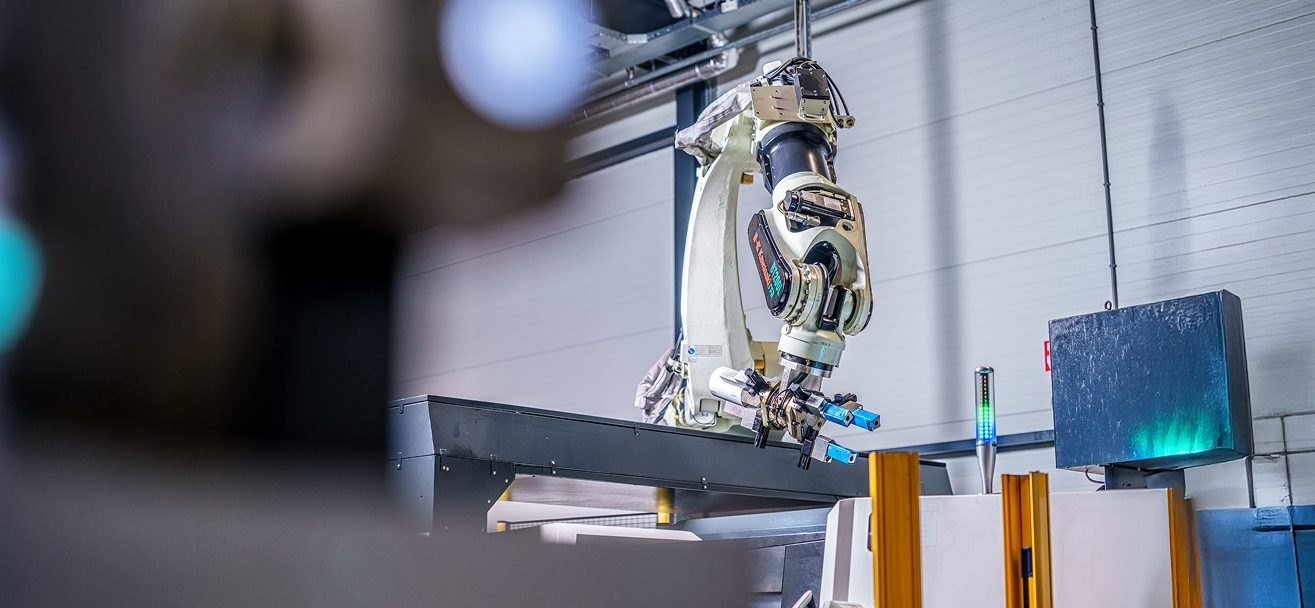

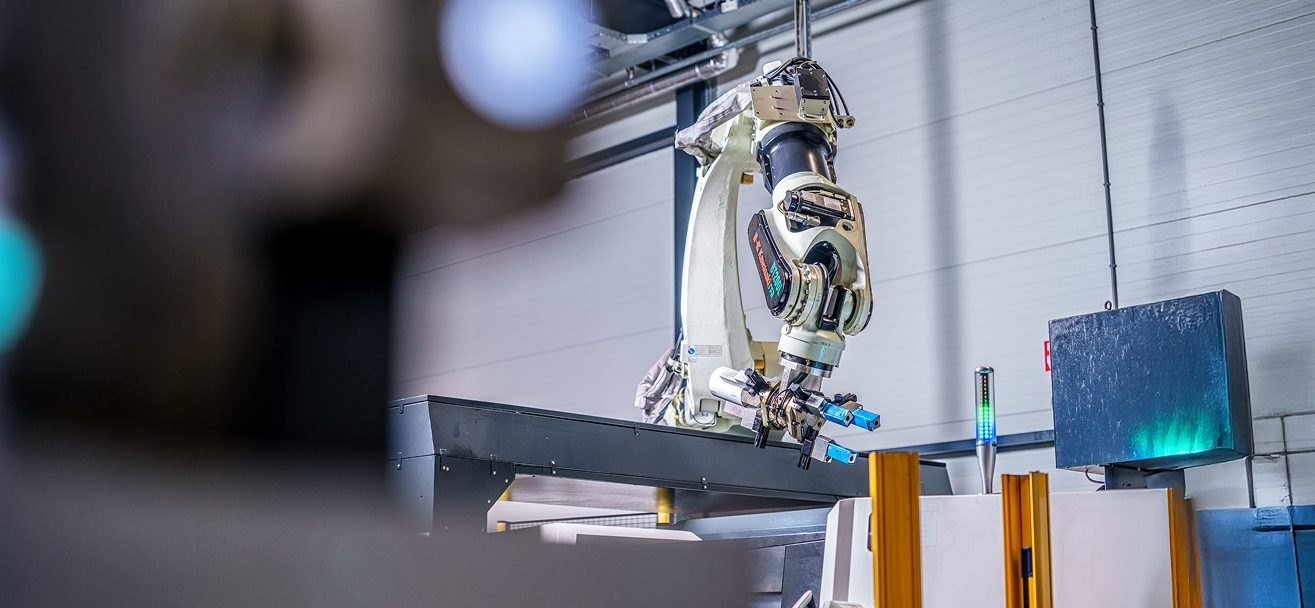

Robotization

With five fully robotized machines, four lathes, and a 5-axis milling machine, we produce continuously and efficiently. This allows us to combine precision with maximum productivity.

With five fully robotized machines, four lathes, and a 5-axis milling machine, we produce continuously and efficiently. This allows us to combine precision with maximum productivity.

Our robotic systems ensure continuity and precision. Automated production allows us to reduce costs, shorten lead times, and guarantee consistent quality.

Our robots never stop, precision and continuity, 24/7.

Automation that makes every series equally accurate.

At TMI Group everything comes together: machining, solutions and service. With all disciplines under one roof, we provide total technical solutions. From precision part to complete installation. Big in technology, but strong in every detail.

Robotization plays a central role in TMI's production process. We use automatic loading systems, exchange stations, and 24/7 production capacity. This allows us to achieve a high degree of continuity and predictability. This results in less downtime, fewer errors, and higher output for complex products. The combination of robotization and modern CNC technology makes it possible to efficiently produce both small series and large batches. Customers benefit from consistent quality, short lead times, and optimal cost efficiency.

Robotization allows us to automatically clamp, machine, and inspect complex parts. This reduces error margins and makes production more stable. Robotization offers particular added value for products with precise tolerances and multiple machining operations. In this way, we create reliability, speed, and reproducible quality.

Our 5-axis milling machine offers extensive possibilities for complex geometries. For parts with multiple contours or operations in a single setup, this technology ensures less changeover time, high accuracy, and a more efficient process. This is ideal for high-tech, medical, and industrial applications.

As a full-service production partner, TMI combines machining and service. Our customers have a single point of contact for the entire process. Robotization makes us flexible and scalable, enabling us to respond quickly to changing demand and increasing volumes. We are happy to help you move forward with smart, efficient, and future-proof production technology. Would you like to know more? Contact us for a technical consultation or a tour of our production environment.

At TMI, automated production goes hand in hand with precise process control. We monitor every step of the production process using inline measurements and 3D measurement technology. This allows us to offer certainty to sectors where quality and control must be demonstrable, such as high-tech, food, energy, and medical technology.