Balancing, engraving, and documents for traceable quality control

At TMI, we balance rotating parts up to 60,000 rpm. This is ideal for high-performance applications. Products are engraved with serial numbers and batch codes. Measurement reports, material certificates, and documentation are available upon request. This ensures that audits and quality controls are always transparent.

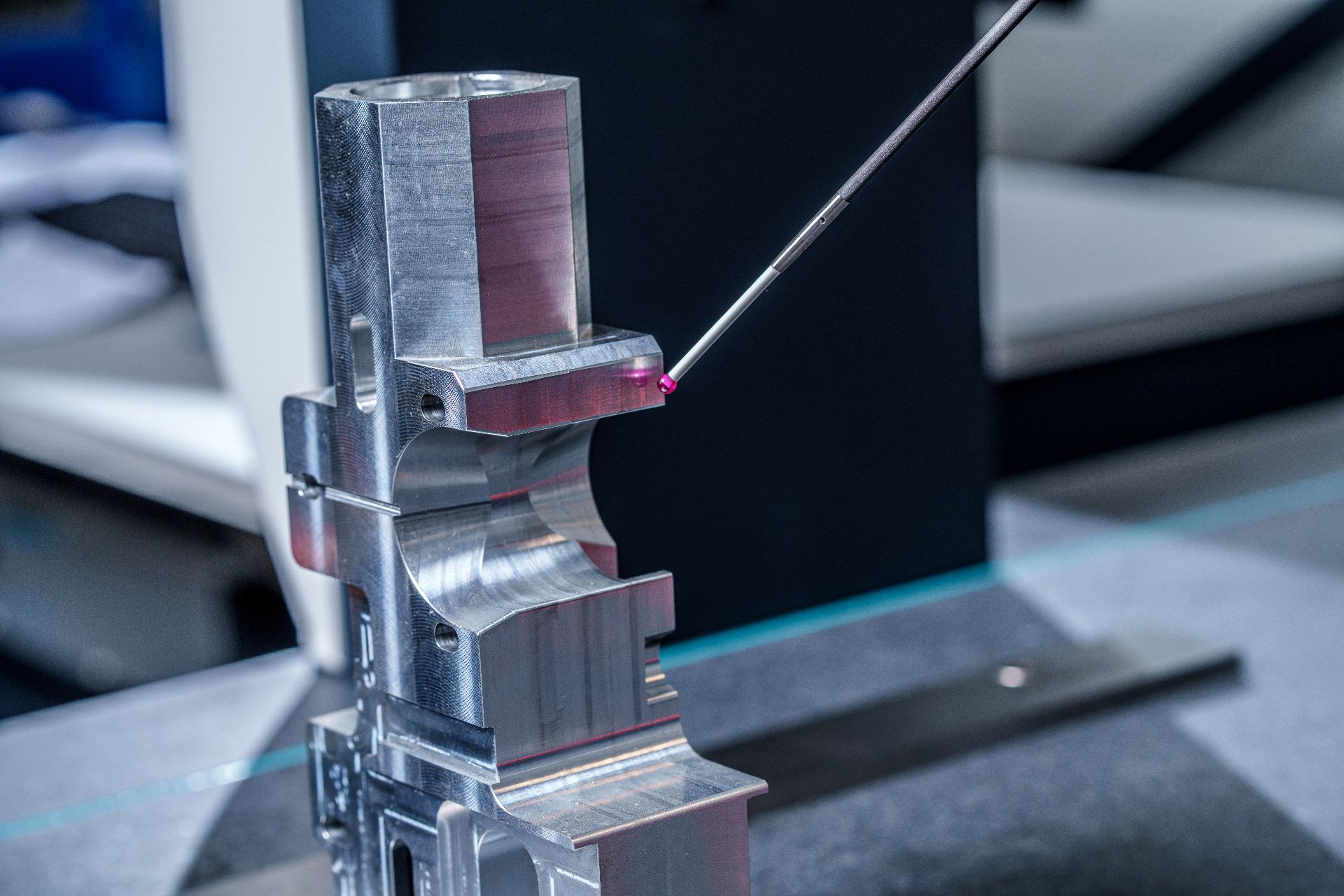

Quality assured by ISO 9001-certified quality management

We offer complete in-house quality control. Whether it concerns prototypes, series production, or critical components, we provide data, certainty, and repeatable quality. Thanks to our ISO 9001 certification, high-quality measuring equipment, and strict process monitoring, you know exactly what to expect.