Oil and gas

For the oil and gas sector, TMI Group supplies high-quality metal components that are resistant to external conditions. Our precision machining meets strict quality requirements and comes with full traceability and dimensional reporting.

For the oil and gas sector, TMI Group supplies high-quality metal components that are resistant to external conditions. Our precision machining meets strict quality requirements and comes with full traceability and dimensional reporting.

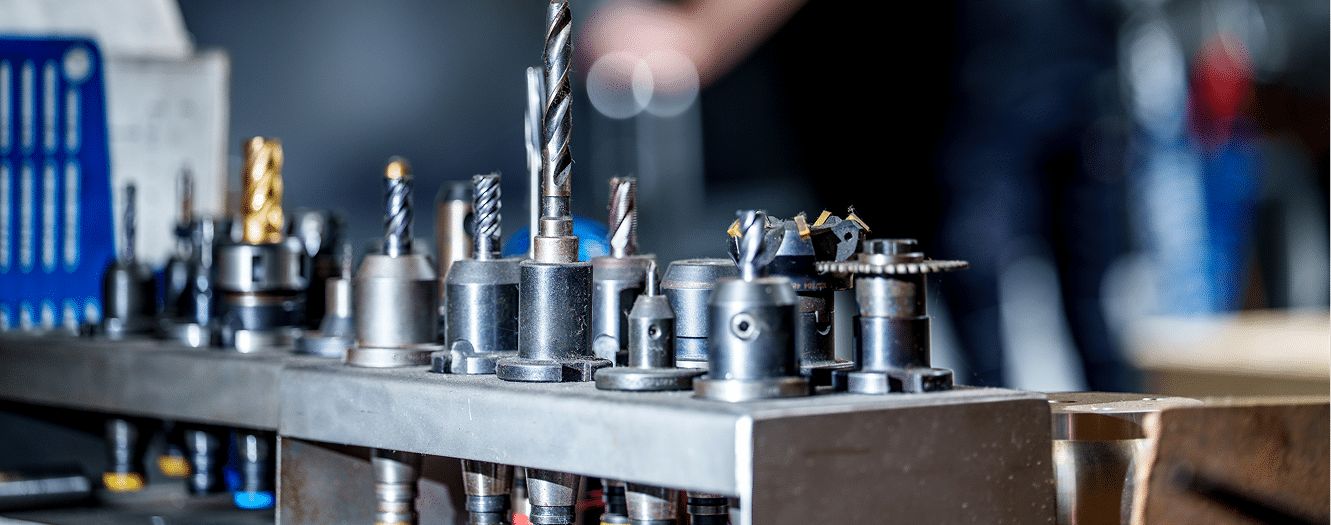

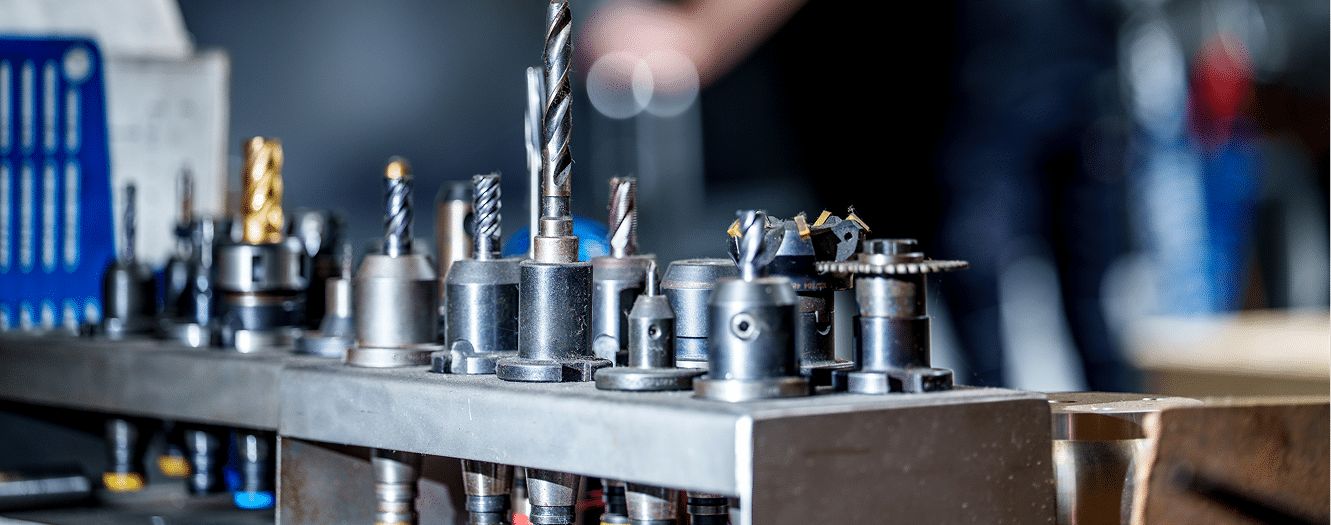

TMI manufactures and processes components for oil and gas installations, both onshore and offshore. These include drill pipes and connecting rods, valve and valve components, and precision mechanical parts for industrial installations. We work with high-quality steels, stainless steel, and special alloys for high pressure, temperature, and corrosive environments. By using 3D measurement reports, we offer full traceability and consistent quality.

TMI Group offers certainty: components that perform under harsh conditions, with demonstrable quality and traceable production data. Through automated processes, accurate checks, and reliable procedures, we deliver dimensionally stable components that comply with international standards. Our strength lies in consistency and short lines of communication, the basis for long-term cooperation.

We think ahead, continuously improve and deliver with pride.

Technology changes rapidly, so we continue to invest continuously.

At TMI Group everything comes together: machining, solutions and service. With all disciplines under one roof, we provide total technical solutions. From precision part to complete installation. Big in technology, but strong in every detail.

The oil and gas industry requires components that can withstand exceptional conditions. TMI produces components that can withstand high pressure, heavy loads, vibrations, and aggressive media. Thanks to our experience with complex materials and automated CNC processes, we deliver precise components with minimal tolerances. TMI takes an integrated approach, ensuring reliable, repeatable quality. We document every step of the process, giving operators, engineers, and QA teams complete insight into the origin and measurement data.

Our CNC machines are equipped for high-quality machining of special alloys and corrosion-resistant metals. This enables us to deliver precise fit dimensions, perfect surface roughness, and repeatable quality for critical systems. Ideal for valves, connections, and structural components used in the oil and gas sector.

Our specialists combine craftsmanship with automated measuring processes. They understand the requirements of the oil and gas industry and translate these into accurate machining with minimal variation. TMI supplies components to the oil and gas sector that support safety, reliability, and a long service life.

TMI is your partner for high-quality, traceable, and sustainable components for the oil and gas industry. We combine precision, quality, and technical expertise to strengthen your processes. We are happy to work with you to improve efficiency, safety, and continuity. Would you like more information about the possibilities or to schedule a no-obligation consultation? Please feel free to contact us.

Every component produced by TMI is given a unique serial number that is linked to material certificates, measurement reports, and process data. This simplifies audits and guarantees full traceability, which is essential in a sector where safety and quality are paramount. This means you know exactly how each component has been manufactured and inspected.